Custom Cut Sizes

Koma Celuka Sheets are Custom Cut-to-Length and width offering an unlimited range of PVC trim. Below is sample of lengths and sizes, tailored to meet in-store and special-order needs.

The custom cut program utilizes a Computerized Panel Saw capable of handling material sizes up to 4 feet wide and 14 feet in length, allowing for precise and customizable cuts.

KOMA CELUKA

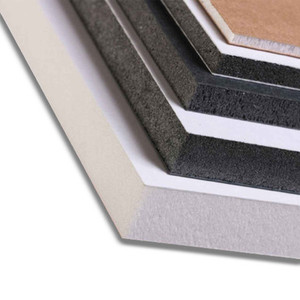

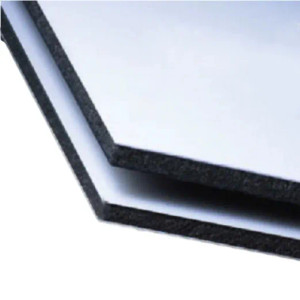

What makes KOMA’s trim boards unique is how they utilize the CELUKA process, which sets it apart from all other cellular PVC trim competitors. In the unique KOMA CELUKA process, special extrusion tooling allows for quick cooling of the outer surface of the CELUKA PVC material, and an inward expansion of the cellular PVC. This results in a hard shell with a strong cellular core, making them uniform in dimension.

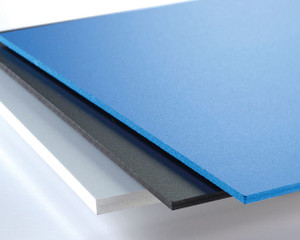

Engineered in Germany, but made here in the USA, CELUKA is the most cost effective and hardest pre-finished board in the market. With a matte finish look, it feels and works just like wood but will not dent, ding, swell or rot even under the harshest weather conditions. CELUKA is durable, workable and economical and here’s just a few more reasons why it’ll last a lifetime.

CELUKA TRIM IS:

- Bug, moisture, and rot resistant

- Contracts 50% less than free foam PVC

- Every piece comes in exact thickness, every time

- No special installation tools needed

- Pre-sanded for best paint adhesion

- 100% ready to use

- Reversible — wood grain and smooth sides

When compared to free foam PVC products, the biggest difference is the durability. Free foam products can easily become damaged on the jobsite with dents or dings. However, with CELUKA, the exterior shell is so hard that it is completely resistant to damage. Builders will experience the KOMA difference as they nail, glue, drill, rout, and cut the trim products using their regular tools. CELUKA trim can even be sanded like wood without flash marks and can be shaped with heat. Since CELUKA trim boards come pre-sanded, they only need one coat of paint, saving time and money over PVC free foam, which needs multiple coats. Check out the below chart to see how CELUKA products are the “exceptional” to PVC Free Foam’s “acceptable.”